Spray Drying solutions for R & D and Production

Mumbai, Maharashtra

Monday to Saturday

Spray drying is used to create dry powders from liquid solutions or suspensions. The process can be used for various products and materials, including food, pharmaceuticals, and ceramics. Pilot spray dryers are smaller-scale versions of industrial spray dryers and are used to test the feasibility of a product before large-scale production. Is pilot spray drying right for your product or material? This blog post will provide everything you need to know about lab spray dryer, including how they work and what benefits they offer.

A pilot spray dryer is a special type of drying machine that uses a spray nozzle to disperse small droplets of liquid material into a stream of hot air. This process causes the instant evaporation of surface moisture, allowing for rapid and uniform drying.

Unlike traditional drying methods, such as oven baking or freeze-drying, a lab spray dryer can be much faster and more efficient. The end product is often more uniform in texture and particle size since heat is applied evenly throughout the material, providing better control over the output quality. Additionally, it allows large-scale production with minimal inputs because most energy goes directly towards evaporating moisture instead of heating the whole material. All these benefits make pilot spray dryers ideal for any industrial process where speed and efficiency are paramount.

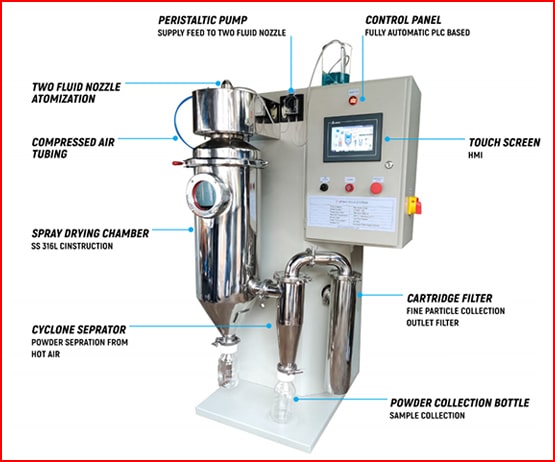

A pilot spray dryer is an intricate machine that can be used for various applications in many industries. It begins by transferring liquid product to the drying chamber, where atomisation happens with hot air from a gas burner. During the atomisation process, a significant part of the water evaporates away, leaving behind the product as a fine solid powder. Pilot spray dryer manufacturers offer products with many variables, such as flow rate, temperature control, system containment and dust collection efficiency. Different manufacturers have various capabilities and provide various design options, so choosing the right one for your purpose may require careful research. In short, pilot spray dryers provide a quick and efficient way of producing powders for further applications.

Pilot spray dryers are a valuable tool for any business or institution looking to improve the quality of their production processes and products. Popular applications for pilot spray dryers include improving the solubility, shelf life, and organoleptic properties of food ingredients and pharmaceuticals; drying molten substances into free-flowing powders; crystallising solutions; agglomerating wet materials or producing complex microstructures through a high shear application. By utilising a pilot spray dryer, businesses can gain greater control over the quality of their products while saving time and money. Furthermore, laboratories can use this technology to create small batches of a product to test its performance before investing in large-scale production. In short, pilot spray dryers are an essential resource for business owners looking to take full advantage of innovative technology and ensure that their process runs at optimum efficiency.

Pilot spray dryers are an essential component of many industrial processes, used to reduce liquid solutions into powder or granules instantly. To ensure that the process runs smoothly and safely, spray dryer suppliers suggest knowing the basics of how to operate a pilot spray dryer properly. The most important step is to properly set up the equipment, which involves carefully checking the nozzle size and calibration, setting the temperature and flow rate according to your requirements, and making sure that the area around the machinery is residue-free. Additionally, it is important to keep safety in mind when working with this type of machinery by wearing proper protective equipment such as gloves and face masks, avoiding direct contact with heated parts of the machine, and regularly monitoring noise levels for safety reasons. With these precautions, you can have peace of mind while using a pilot spray dryer and enjoy its efficiency!

If you're operating a pilot spray dryer, it's important to prepare for potential problems that can arise during operation. for Pilot spray dryer manufacturers can help prevent waste and costly downtime. Since there are so many potential failure points of a pilot spray dryer, from the feed system to the main chamber, familiarise yourself with the diagnostic protocols specific to your set-up and all its components. You should always prioritise safety when troubleshooting, adhering closely to manufacturer instructions and following any safety warnings in the documentation. Additionally, understanding key concepts such as energy balance and material balance may lead you closer to solving any problems you come across while working with your pilot spray dryer.

A pilot spray dryer can offer many benefits over other drying methods, and it is a versatile tool that can be used in various applications. When considering using a pilot spray dryer in your process, it is important to understand how the machine works and what factors come into consideration when choosing one. Proper operation of the pilot spray dryer is essential for safety and product quality, so follow all the guidelines outlined in this blog post. Are you looking for spray dryer suppliers? Get in touch with us!

Head of Innovation

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Benenatis mauris. Vestibulum ante ipsum primis in industry, logistics, finance, business orci ultrices venenatis mauris.

Marketing

92%

Marketing

82%